SMART Bilge monitor – 15ppm bilge alarm

15ppm bilge alarm

The SMART BILGE 15ppm Oil Content Monitor with 15ppm bilge alarm was developed in 2005 for real time oil analysis to meet and exceed the requirements for MEPC.107(49) regulations.

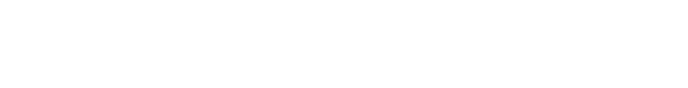

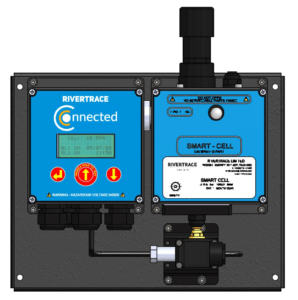

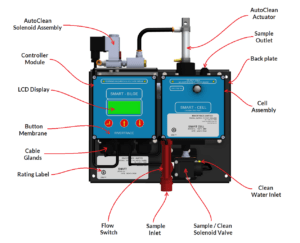

The SMART BILGE 15ppm monitor and alarm is made up of 2 key components:

- the SMART BILGE ‘Module’

- the SMART ‘CELL’ measuring cell

Developed by Rivertrace, the SMART CELL utilises a unique Detector Array Technology. This enables the OCM to run real time oil analysis of all three oil types (HFO, Diesel and Emulsions) simultaneously without the need for re-calibration.

This innovative design allows for simple routine maintenance of the OCM, while maintaining optimal operating conditions

15ppm bilge alarm

The SMART BILGE 15ppm Oil Content Monitor with 15ppm bilge alarm was developed in 2005 for real time oil analysis to meet and exceed the requirements for MEPC.107(49) regulations.

The SMART BILGE 15ppm monitor and alarm is made up of 2 key components:

- the SMART BILGE ‘Module’

- the SMART ‘CELL’ measuring cell

Developed by Rivertrace, the SMART CELL utilises a unique Detector Array Technology. This enables the OCM to run real time oil analysis of all three oil types (HFO, Diesel and Emulsions) simultaneously without the need for re-calibration.

This innovative design allows for simple routine maintenance of the OCM, while maintaining optimal operating conditions

The SMART CELL utilises a unique Detector Array Technology, developed by Rivertrace, allowing the OCM to analyse all three oil types (HFO, Diesel and Emulsions) simultaneously without the need for re-calibration. This innovative design allows for simple routine maintenance of the OCM while maintaining optimal conditions.

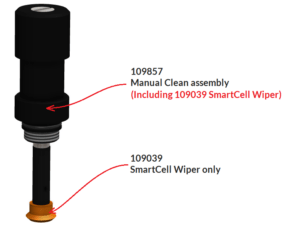

Optical cell fouling is recognised as a leading cause of monitor malfunction or incorrect reading. A manual cell cleaning device is included as standard to easily enable routine maintenance.

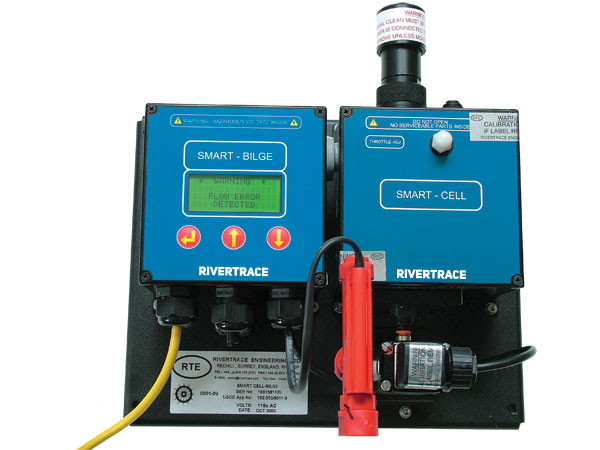

Replacement calibrated measuring cells can be purchased for easy change over on board the vessel and calibration check kits enable the crew to demonstrate the monitor is within factory calibration to PSC Surveyors.

- Digital Certifications

- Automated electronic calibration reminders

- Over 50 approved service centres worldwide for calibration checks and service

- Separate Calibrated SMART CELL to allow easy exchange

- Test button for demonstration of alarm points to port state control

- Real time oil analysis

- MEPC.107(49) Bilge Water Discharge

- Oily Water Separator

- Deck Drains Discharge

- Rig Slop Tank Discharge

- Air Cooler Drains Discharge

- 5PPM Alarm – The Smart Cell Bilge Alarm is readily available as a 5ppm version if required.

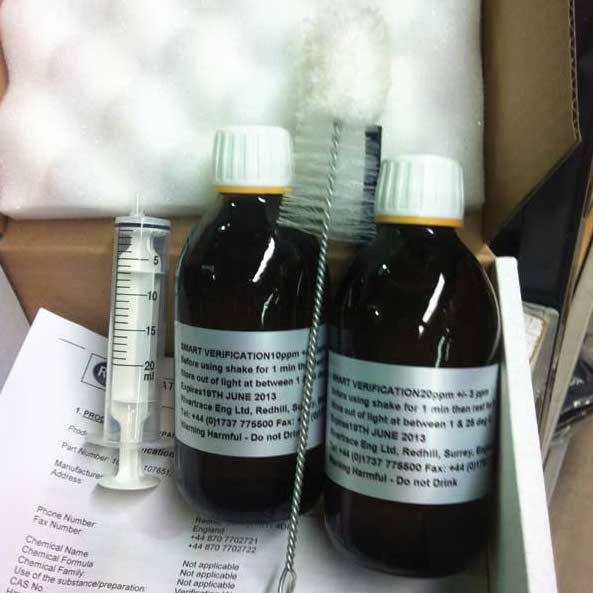

- Autoclean – our pneumatic autoclean solution has been designed to ensure the measuring cell glass tube his kept free from fouling. Cell fouling is recognised as a leading cause of monitor malfunction. Fitting the autoclean removed the need for the ship’s crew to remember to clean the cell manually.

- Flowswitch – The flowswitch option has been designed to ensure that bilge water is flowing through the measuring cell when in monitoring mode. An error is shown on the display if there is no flow. The flowswitch monitors the flow of water through the cell. This ensures that the flow cannot be shut off accidentally or maliciously. In case of no flow, the Smart Bilge will close the overboard discharge valve.

- Hazardous Environments (Zone 1 & 2) – The SMART BILGE can be offered in an explosion proof cabinet

- RT CONNECTED – MEPC.107(49) OWS Discharge data can be captured and shared digitally to the cloud which can then be integrated into electronic ORBs.

All options can be ordered from new or retrofitted to existing Rivertrace Smart Bilge monitors.

| Measurement | |

| Oil types: | HFO, Diesel and Mixture C (IMO defined) |

| Clean water calibration: | +/- 2ppm of factory set values |

| Oil range: | 0 – 40 ppm |

| Accuracy oil + solids: | +/- 5ppm up to 30 ppm |

| Solids discrimination: | 100ppm Iron Oxide in 10 ppm Diesel |

| Response time: | < 5 sec (oil reading) |

| Alarms | |

| Oil alarm 1 setpoint: | 1 – 15 ppm user adjustable |

| Oil alarm 2 setpoint: | 1 – 15 ppm user adjustable |

| Oil alarm 1 delay: | 0 – 5 seconds user adjustable |

| Oil alarm 2 delay: | 0 – 600 seconds user adjustable |

| Input / output | |

| Analogue output: | Active 4-20mA / 0 – 20mA |

| Switch inputs: | 2 x switch inputs for separator and backflush status |

| Data storage and retrieval | |

| Calibrate on data storage: | Stored in cell |

| IMO required data: | Stored in Control enclosure |

| IMO required data retrieval: | Via LCD display, RS 232 comms link or USB |

| System and supply | |

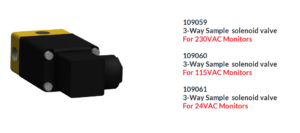

| Supply voltage: | 115 or 230V AC, 50 – 60Hz |

| Supply voltage Consumption: | < 50 VA incl. solenoid valve |

| Supply voltage tolerance: | +/- 15% |

| Projected life: | > 50,000 hrs |

| Protection class: | IP 65 |

| Approvals: | MEPC 107(49) – DNV-GL, USCG, CCS, , Russian Register, Transport Canada. |

| Weight: | 3.2 Kg / 7.05lb |

To ensure the highest precision and reliability of your equipment we highly recommend Annual Calibration.

If your device is registered with the Rivertrace portal, you can request a Calibration Check via the portal.

Calibration option 1 – Annual Calibration Check

-

Annual Calibration Check – This would require the Calibration Check Kit (109996) our Rivertrace Approved Engineer would perform a calibration check and issue an annual certificate.

-

Calibration Kit Required – To conduct an annual calibration check, the Calibration Check Kit (Part No: 109996) is necessary.

-

Certified Engineer Services – A Rivertrace Approved Engineer will administer the calibration check.

-

Certification – Following the successful calibration, an annual certification will be issued.

Calibration option 2 – IMO 5 Year Calibration

-

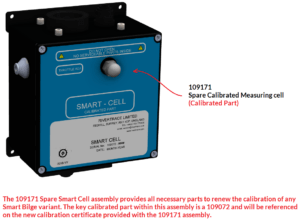

IMO 5 Year Calibration – Measuring Cell Replacement (109171) this comes with the 5-year factory calibration certificate.

Calibration option 3 – Complete Manufacturer’s Calibration Process

-

Return your unit to Rivertrace – Please send your unit back to us to fulfill the calibration process and ensure your equipment is operating with optimal precision.

Please contact us to schedule your annual calibration check and maintain your equipment’s optimal performance

Service Options – SMART Bilge

-

Fault Diagnosis and Repair – Comprehensive troubleshooting to identify and fix issues.

-

Installation and Upgrades – Seamless setup and enhancement of your monitoring equipment.

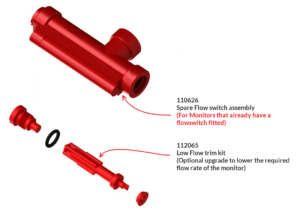

- Optional Add-Ons Available – Choose additional features such as Flow Switch and Autoclean.

- Servicing – Fault Finding/Repair or installation /upgrades to the monitor with optional extras are available (flow switch & autoclean).

Please contact us to discuss service requirements or to customise your monitoring solutions.

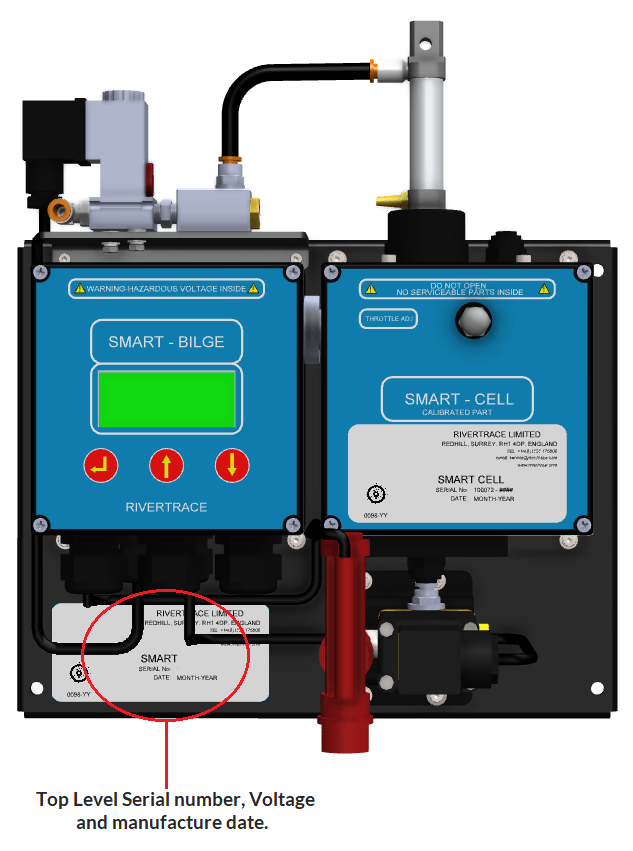

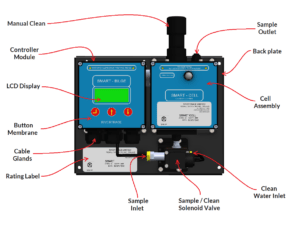

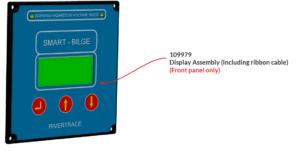

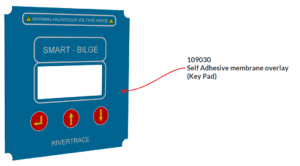

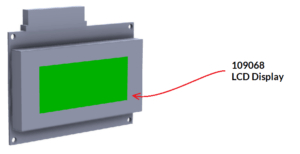

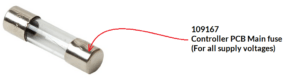

Please use this page to identify the part number of the part that you require.

SmartBilge assembly overview

To ensure the correct parts are purchased, the serial number and voltage of your SmartBilge should always be provided to Rivertrace when ordering spares.

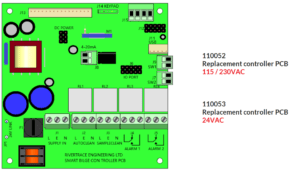

Main Spare Parts

When purchasing a replacement controller PCB, it is important to state any special settings that may be required from the list below:

- 5ppm Maximum alarm set-points

- Autoclean enabled

- Flow switch enabled

If no special settings are required, the standard software settings shall be applied that consist of the following:

- 15ppm Maximum alarm set-points

- No Autoclean capability

- No flow switch capability

Installation instructions for your replacement controller PCB can be found here.

Installation instructions for your replacement controller PCB can be found here.

“Lorem ipsum dolor sit amet, consectetur adipiscing elit. Aenean quis leo mauris. Curabitur tempor orci sapien, quis mattis ante tincidunt vestibulum. Suspendisse potenti.”

Martin Saunders

CEO, Company Name

“Lorem ipsum dolor sit amet, consectetur adipiscing elit. Aenean quis leo mauris. Curabitur tempor orci sapien, quis mattis ante tincidunt vestibulum. Suspendisse potenti. Donec rhoncus porta risus, et molestie nulla tristique nec. Suspendisse potenti.”

Martin Saunders

CEO, Company Name

“Lorem ipsum dolor sit amet, consectetur adipiscing elit. Aenean quis leo mauris. Curabitur tempor orci sapien, quis mattis ante tincidunt vestibulum. Suspendisse potenti. Donec rhoncus porta risus, et molestie nulla.”

Martin Saunders

CEO, Company Name

Our services

Since being founded in 1983 in the UK, we have a developed a deep understanding of the environmental regulations that relate to oil-in-water monitoring.

Rivertrace is regarded as a leading authority on the interpretation of the environmental regulations into practical recommendations and solutions for marine, offshore and industrial applications.

We apply this knowledge in two ways:

- To design oil-in-water monitoring devices and systems that create operating efficiencies

- To advise our customers on the most appropriate product solutions and processes for their operations