In January 2020, the IMO 2020 global sulphur cap came into force to improve air quality, preserve the environment and protect human health. To comply with this sulphur reduction a popular solution is to install an exhaust gas cleaning system (EGCS).

For this, wet scrubber systems use wash water to remove the pollutants from the exhaust gas. Therefore the wash water being discharged must be monitored at all times to ensure it is within the limits set by the regulating body. There are IMO regulations for water quality parameters including Polycyclic Aromatic Hydrocarbons (PAHs), pH and turbidity prior to discharge into the ocean.

With over 35 years experience designing equipment for the marine environments, Rivertrace has developed our SMART ESM. The SMART ESM designed to MEPC.259(68) and MEPC.340(77) and is suitable for both the inlet and outlet of a EGCS, measuring and recording the required parameters of PAH, Turbidity, Temperature and pH. The monitor can be installed on new build of retrofit systems and can accommodate open-loop, closed-loop and hybrid scrubber systems.

The innovative measuring cell design allows for unique Plug and play maintenance design. Each measurement parameter is enclosed in a separate cassette slotted inside the measuring cell around the sample tube. This allows the calibrated parts to be swapped without the need of isolating the sample which flows through a glass tube in the centre of the cell.

- Compatible with Open Loop, Closed Loop and Hybrid systems

- Flexible configuration at each sample point for the relevant measurement parameters – PAH, pH, Temperature and Turbidity

- Suitable for inlet and outlet monitoring

- Plug and play design for each measurement parameter for easy maintenance

- Calibration Check Kits available

- On screen historical data graphs showing Instant/ Hourly/Daily/Weekly figures

- Automatic cleaning of optical path

- Exhaust Scrubber Washwater Discharge

- MEPC 259(68)

At Rivertrace we understand every EGCS is different, and we can tailor our system to accommodate the specific parameters and requirements for the scrubber and vessel.

We offer 2 main designs for our equipment which can be customised further with additional components based on technical requests.

Option 1 – Frame Mounted. This option is based on a modular design all mounted onto a frame / backplate. It consists of a cooled cabinet housing the Control Module and Measuring Cell with a separate enclosure for the electronics.

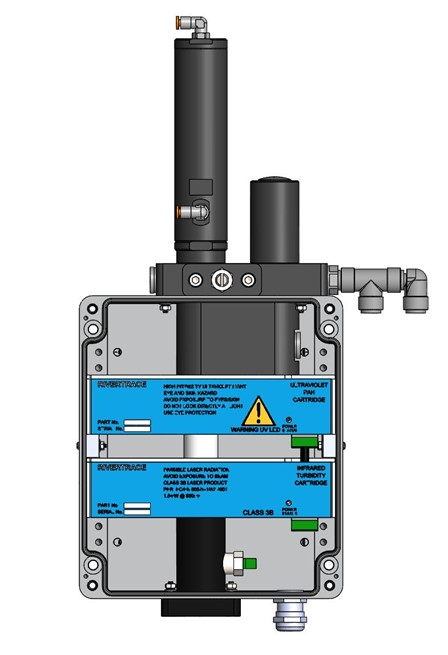

Option 2 – Box Mounted. This option is based on a twin enclosure design.

It consists of a cooled cabinet housing the Control Module and electronics and a separate compartment for the Measuring Cell and sample conditioning equipment.

Other optional components include:

- Sample Heat Exchanger should be included is the sample temperature is above 40degC

- Motor / Pump should be included if the pressure in the sample line is below 0.5bar

SMART ESM – Frame Mounted (FM) Configuration with Sample Heat Exchanger and Motor Pump

SMART ESM – Box Mounted (BM) Configuration with Sample Heat Exchanger and Motor Pump

SPECIFICATION

| PAH Range | 0μg/L to 4500μg/L |

| PAH Accuracy | 5% of measurement reading |

| PaH Measurement Principle | UV Fluorescence |

| Turbidity Range | 0 – 500 NTU |

| Turbidity Accuracy | 0.1NTU up to 100 NTU, 1NTU thereafter. |

| Turbidity Measurement Principle | IR Scattering |

| pH Range | 0 – 14 pH |

| pH Accuracy | 0.1 pH |

| pH Measurement Principle | pH Electrode |

| Sample / Clean Water Temperature range | 0oC to 40oC*

*Higher optional with Heat Exchanger |

| Sample / Clean Water pressure range | 1 to 9 Bar |

| Optimum Measuring pressure (Sample / Clean) | 3 Bar |

| Required Air Supply Pressure Range | 4 – 6 Bar |

| Compressed Air normal / average consumption | 450mL / Hr |

| Sample / Clean Water Flow rate range | 1 to 4 LPM |

| Ambient Temperature range | 0°C to 50°C |

| Supply Voltage | 230 VAC 50/60 Hz |

| Outputs | MODBUS

4-20mA |

| Response Time | 266 seconds at 1l/m flow rate |

| Storage | Internal SD Card

Downloadable to External USB |

| IP Rating | IP66 |

| Wetted Parts Material | uPVC, Nylon, Black acetal copolymer and peek |

| Approvals | DNV Type Approval – MEPC.259(68) and MEPC.340(77) |